News

AJ Adhesives, Inc. is a leading vendor of industrial adhesives

Water-Based Adhesive Troubleshooting Guide for Lamination Applications

AJ Adhesives’ Water-Based Adhesive Troubleshooting Guide for Lamination Applications

January 22, 2026

Water-Based Adhesive Troubleshooting in Single-Face & Lay-Flat Applications

Water-based adhesives are a staple in single-face and lay-flat lamination because they offer strong bonds, cleaner machinery, and compatibility with a wide range of paper and board constructions. However, when conditions change on the line, even small variables can create quality issues. This water-based adhesive troubleshooting guide is designed to help operators, supervisors, and engineers quickly identify common lamination problems, understand what’s causing them, and make informed adjustments before scrap and downtime increase.

Why Knowing What to Look for in Water-Based Adhesive Troubleshooting Matters for Lamination

Unlike hot melts, water-based lamination adhesives depend on controlled moisture absorption and evaporation to form a proper bond. When that balance is disrupted, defects appear fast.

Effective water-based adhesive troubleshooting starts with recognizing that most issues are not caused by the adhesive alone. Substrate moisture, board density, temperature, compression, and application consistency all play a role in the final sheet quality.

A consistent troubleshooting approach reduces trial-and-error adjustments and helps stabilize production.

Water-Based Adhesive Troubleshooting for Single-Face & Lay-Flat Lamination 5 Most Common Issues:

This section focuses on the most common lamination defects seen in corrugated and paperboard operations and outlines what to check first before blaming the adhesive and looking for new products.

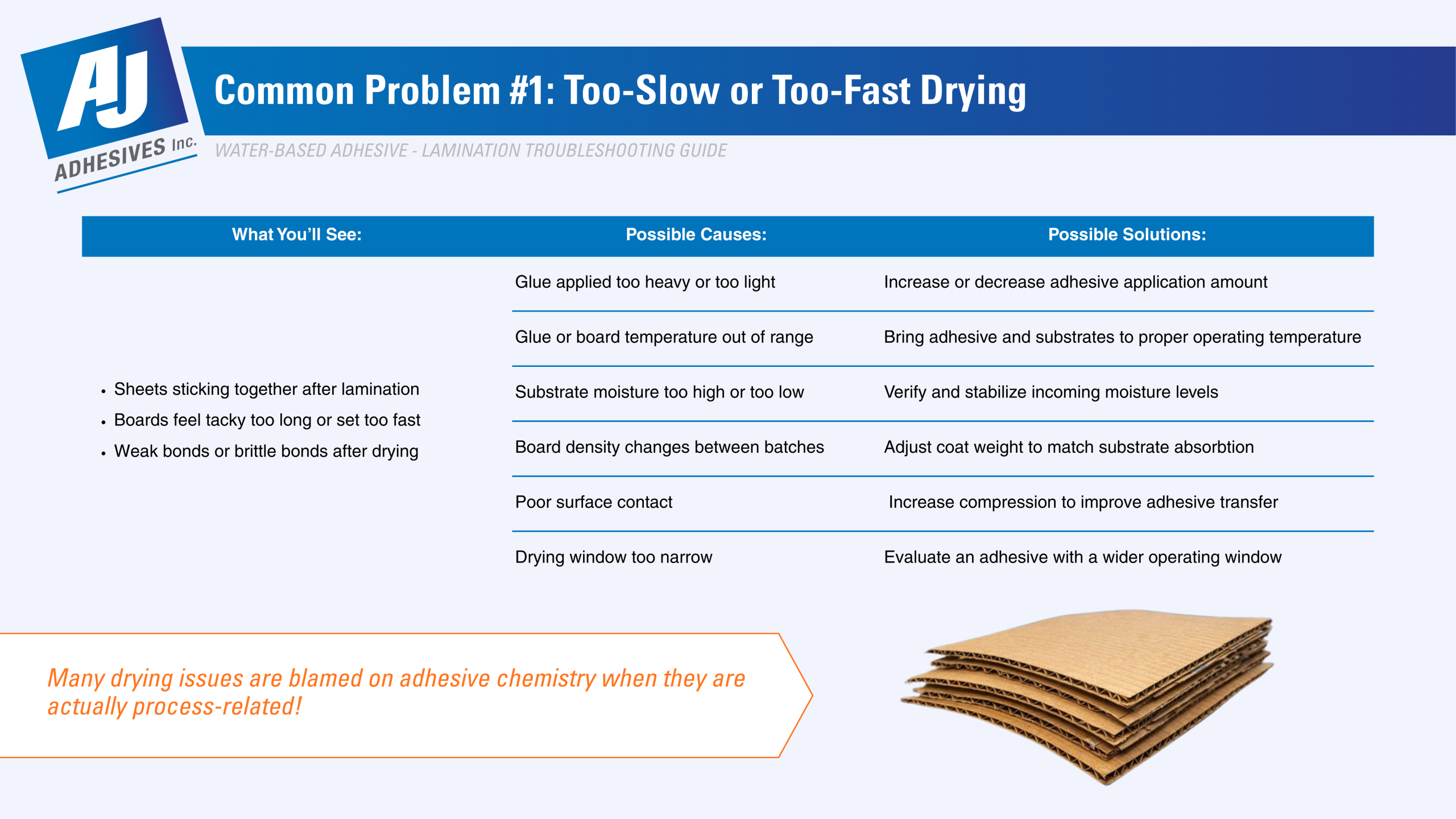

Common Problem #1: Too-Slow or Too-Fast Drying

Visual indicators

- Sheets sticking together after lamination

- Boards feel tacky too long or set too fast

- Weak bonds or brittle bonds after drying

Cause → Solution

- Glue applied too heavy or too light → Increase or decrease adhesive application amount

- Glue or board temperature out of range → Bring adhesive and substrates to proper operating temperature

- Substrate moisture too high or too low → Verify and stabilize incoming moisture levels

- Board density changes between runs → Adjust coat weight to match substrate absorption

- Poor surface contact → Increase compression to improve adhesive transfer

- Drying window too narrow → Evaluate an adhesive with a wider operating window

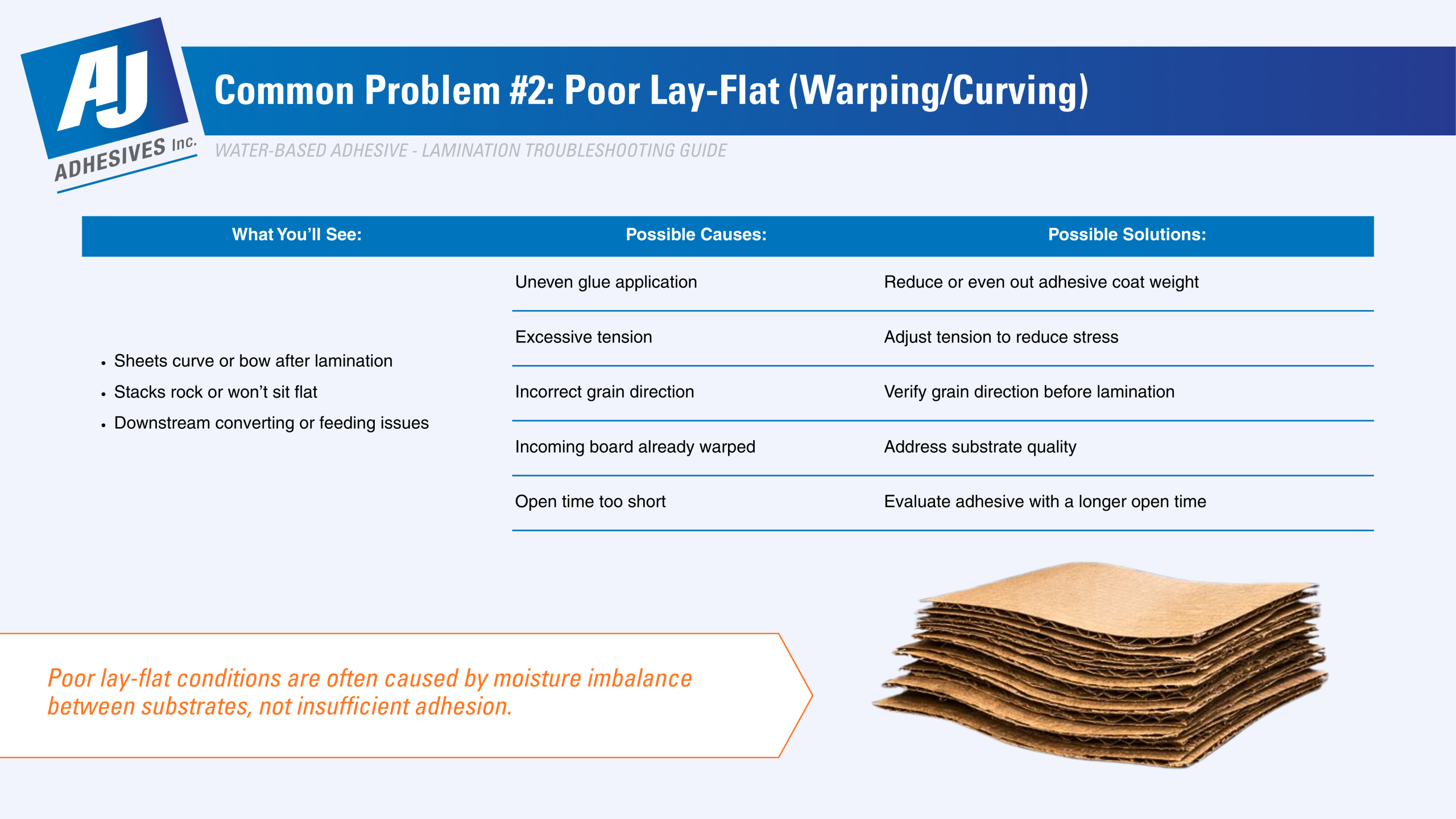

Common Problem #2: Poor Lay-Flat (Warping or Curving)

Visual indicators

- Sheets curve or bow after lamination

- Stacks rock or won’t sit flat

- Downstream converting or feeding issues

Cause → Solution

- Uneven glue application → Reduce or even out adhesive coat weight

- Moisture imbalance between liners → Balance adhesive application across substrates

- Excessive web tension → Adjust web tension to reduce stress

- Incorrect grain direction → Verify grain direction before lamination

- Incoming board already warped → Address substrate quality before changing adhesive

- Open time too short → Evaluate an adhesive with longer open time

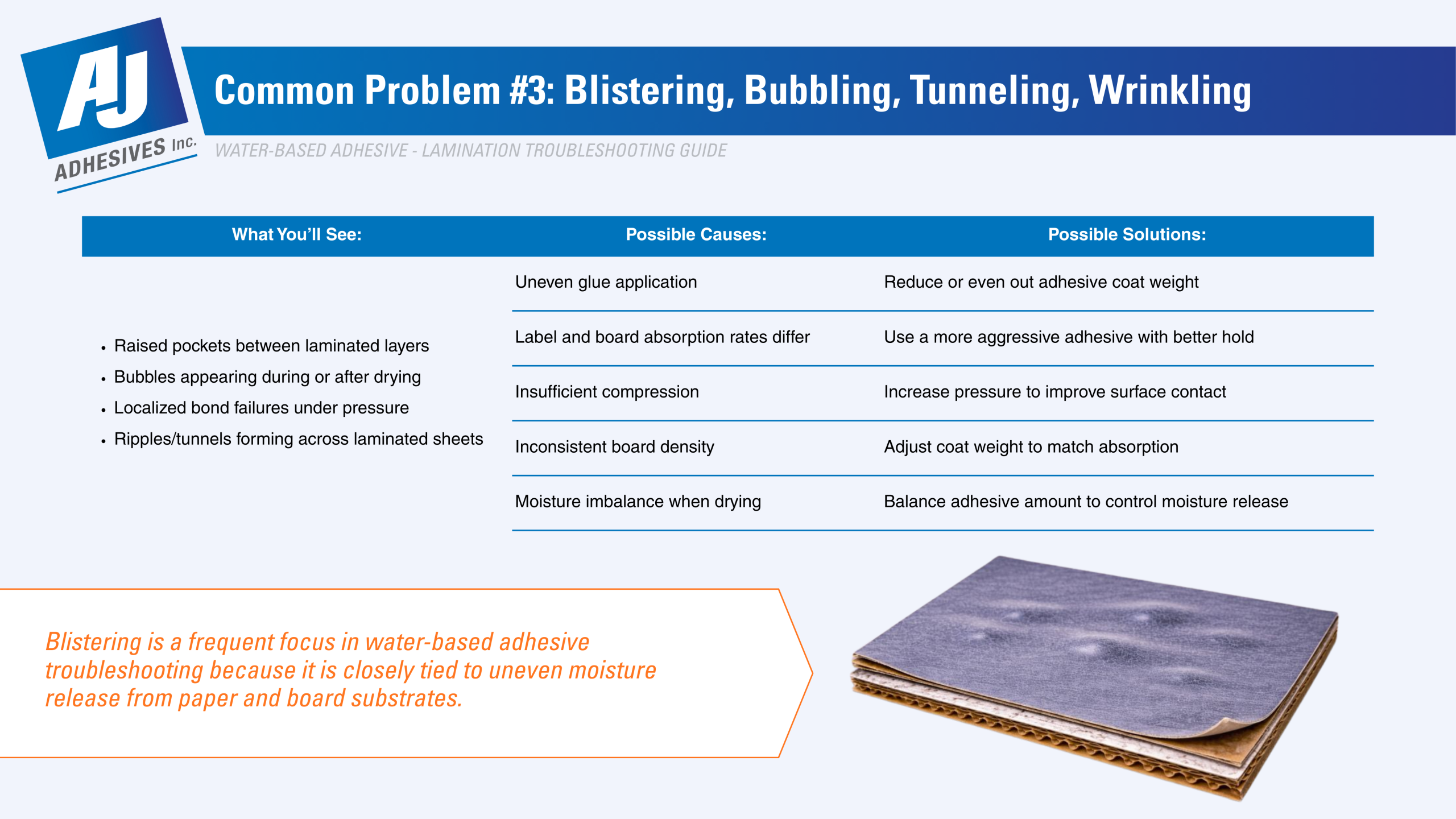

Common Problem #3: Blistering, Bubbling, Tunneling, Wrinkling

Visual indicators

- Raised pockets between laminated layers

- Bubbles appearing during or after drying

- Localized bond failures under pressure

- Ripples/Tunnels across laminated sheets

Cause → Solution

- Uneven glue application across the sheet → Ensure even adhesive coverage across the full width

- Label and board absorb moisture at different rates → Use a more aggressive adhesive

- Insufficient compression → Increase nip pressure to improve surface contact

- Inconsistent board density → Adjust coat weight to match substrate absorption

- Moisture imbalance during drying → Balance adhesive amount to control moisture release

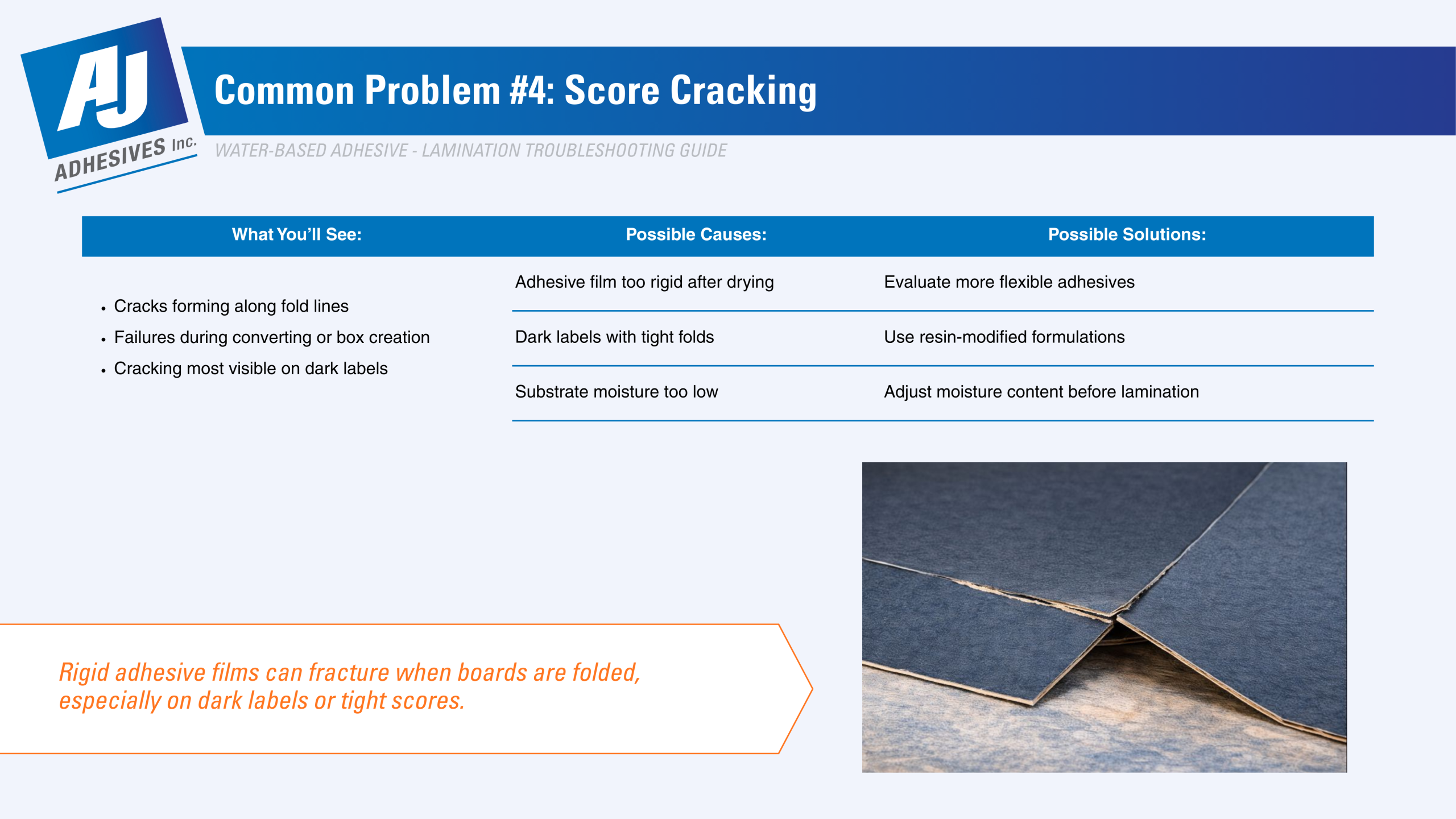

Common Problem #4: Score Cracking

Visual indicators

- Cracks forming along fold lines

- Failures during converting or box erection

- Cracking most visible on dark labels

Cause → Solution

- Adhesive film too rigid after drying → Evaluate a more flexible adhesive

- Dark labels with tight folds → Use resin-modified formulations

- Substrate moisture too low → Adjust moisture content before lamination

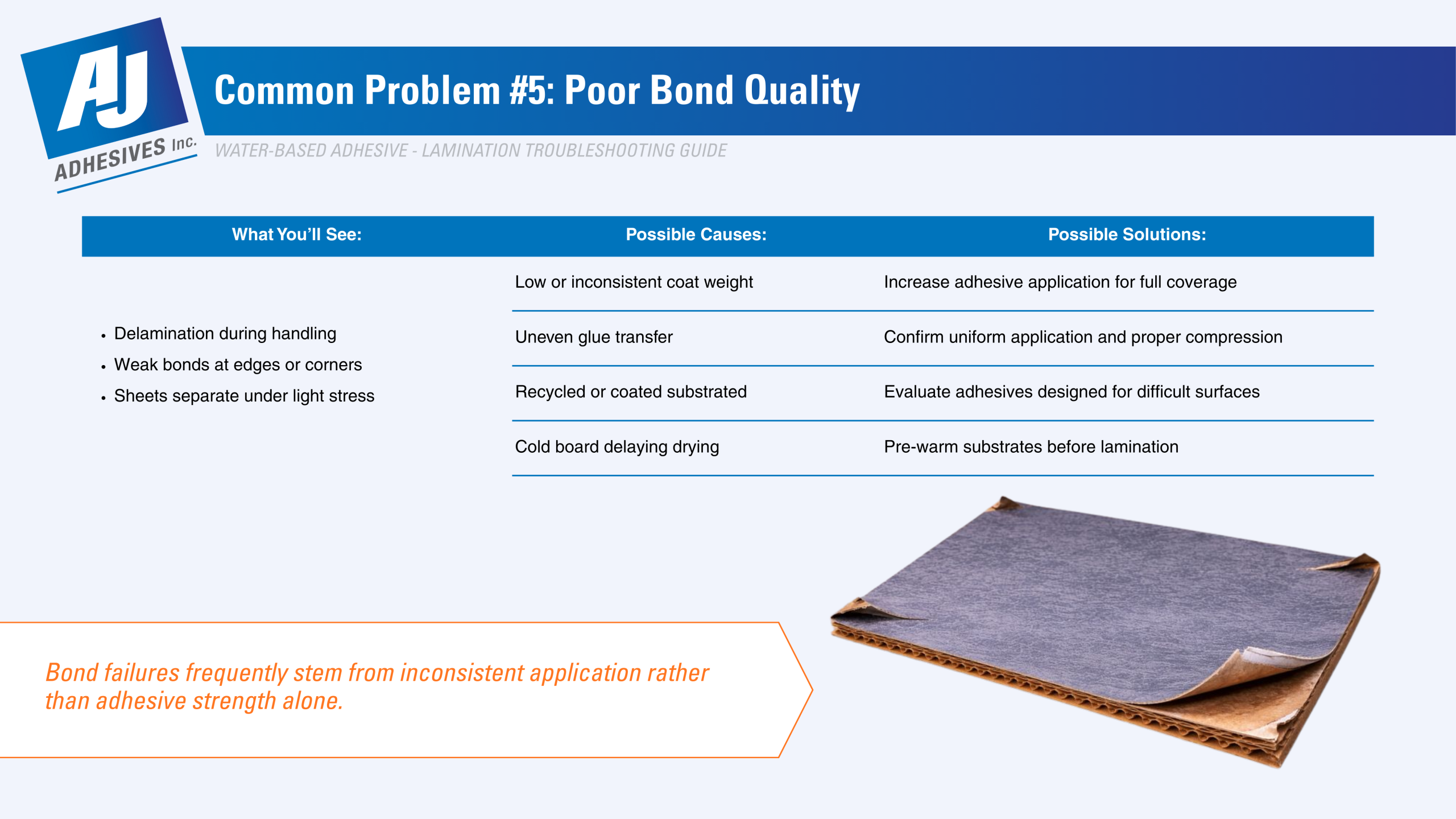

Common Problem #5: Poor Bond Quality

Visual indicators

- Delamination during handling

- Weak bonds at edges or corners

- Sheets separate under light stress

Cause → Solution

- Low or inconsistent coat weight → Increase adhesive application for full coverage

- Uneven glue transfer → Confirm uniform application and proper compression

- Recycled or coated substrates → Evaluate adhesives designed for difficult surfaces

- Cold board delaying drying → Pre-warm substrates before lamination

Best Practices That Support Water-Based Adhesive Troubleshooting

Many lamination issues can be prevented before they occur by following basic best practices:

- Store adhesives and substrates at room temperature

- Maintain paperboard moisture content between 6-10%

- Keep containers sealed to avoid contamination

- Avoid circulating adhesive back into original containers

- Match adhesive viscosity to application method and line speed

Strong process discipline simplifies water-based adhesive troubleshooting and improves your overall line stability and consistency.

SEE OUR DETAILED WATER-BASED ADHESIVES: LAMINATION TROUBLESHOOTING GUIDE HERE

When Process Adjustments Aren’t Enough

If issues persist after attempting to diagnose and take action to prevent further issues arising, it may be time to consult an expert to evaluate what adhesive formulation would be best for your line.

Evaluation points might include viscosity, open time requirements, flexibility or resin modifications, and substrate compatibility. At that point, technical support becomes critical to identifying whether the solution is a formulation change or process refinement.

Final Considerations for Water-Based Adhesive Troubleshooting

Consistent lamination performance comes down to balance. Effective water-based adhesive troubleshooting means understanding how adhesive formulation, substrate conditions, and machine setup work together on the line. When those variables drift, production issues follow quickly.

While many problems can be corrected through process adjustments, recurring issues often signal a deeper mismatch between adhesive selection and current line conditions. AJ Adhesives works directly with production and maintenance teams to troubleshoot lamination challenges on the floor, identify root causes, and implement solutions that hold up for more than a single batch.

If lamination issues are slowing your line or creating unnecessary waste, getting an experienced technical partner involved can help stabilize performance faster and with fewer disruptions.

Ready to find the solution for your line? Contact your AJ Adhesives representative today!

Ready to find the solution for your line? Contact your AJ Adhesives representative today!

To speak with someone immediately, call: (314) 652-4583

For more information or questions, email us at: info@ajadhesives.com

Follow us on LinkedIn & Facebook for more tips, resources, and updates!