News

AJ Adhesives, Inc. is a leading vendor of industrial adhesives

Hot Melt Adhesives vs. Water-Based Adhesives: Choosing by Performance

AJ Adhesives’ Adhesive Selection & Decision Assistance – Hot Melt Adhesives vs. Water-Based Adhesives: Choosing by Performance

February 10, 2026

Choosing the right adhesive is rarely about brand loyalty or habit; it’s about the adhesive’s performance on your line with your materials and your operating conditions. Two of the most common adhesive technologies used in industrial packaging and converting environments are hot melt adhesives and water-based adhesives. Both can deliver strong bonds, but their behaviors are very different once introduced to production variables like speed, temperature, substrate, and downtime.

This guide will break down hot melt adhesives vs. water-based adhesives strictly by their performance characteristics, to help you, as the buyer, maintenance team, or operator, make confident decisions that benefit your line.

Adhesive Performance

Before comparing adhesive types, it’s important to reframe your decision from choosing the “best adhesive” to choosing the one that’s best for you. The “best” adhesive will be the one that delivers consistent bonds with the least disruption to your operation, not the one with the highest lab strength or lowest cost per pound.

Performance should be evaluated in terms of…

- Bond consistency

- Line speed compatibility

- Sensitivity to material variability

- Environmental and operating conditions

- Maintenance and uptime impact

With that lens, let’s compare how hot melt adhesives and water-based adhesives compare.

Hot Melt Adhesives: Performance Characteristics

Hot melt adhesives are applied in a molten state and solidify as they cool. Their performance is closely tied to temperature control and mechanical setup.

Where Hot Melt Adhesives Perform Best

Fast set and immediate handling strength – hot melts develop bond strength quickly, making them well-suited for…

- High-speed packaging lines

- End-of-line case and carton sealing

- Operations where the product needs to move or stack immediately

Minimal drying dependence – because they don’t rely on evaporation, hot melts are less affected by…

- High humidity

- Cold or dry ambient air

- Inconsistent airflow around the bond area

Predictable performance at speed – when temperatures, application weight, and compression are dialed in, hot melts tend to deliver repeatable bonds across long production runs.

Performance Limitations to Consider

Temperature sensitivity – hot melt performance is highly dependent on…

- Tank, hose, and gun temperatures

- Substrate temperature (especially in colder facilities)

Small temperature shifts can impact viscosity, bond formation, and bond strength.

Char and Buildup Risk

Extended run times or improper temperature control can lead to…

- Adhesive degradation

- Nozzle buildup

- Increased maintenance and downtime

Less Forgiving on Certain Substrates

Highly coated, recycled, or variable substrates may require…

- Adjusted application patterns

- Specialty formulations

- More frequent process checks

Water-Based Adhesives: Performance Characteristics

Water-based adhesives rely on water evaporation or absorption into the substrate to form a bond. Their performance is influenced by drying conditions and material properties.

Where Water-Based Adhesives Perform Best

Strong fiber-tearing bonds on paper-based materials – when conditions are right, water-based adhesives can deliver…

- Excellent adhesion to porous substrates

- Uniform coverage across wide surfaces

- Reliable bonds in lamination and converting applications

Lower application temperatures – because they are applied at ambient or moderately elevated temperatures, they reduce…

- Thermal stress on substrates

- Risk of heat-related distortion

Cleaner application systems – water-based systems typically have…

- Less char buildup

- Easier cleanup

- Lower long-term wear on equipment components

Performance Limitations to Consider

Drying time directly impacts speed – on faster lines, incomplete drying can lead to weak bonds that break during handling, so water-based adhesives require sufficient…

- Dry time

- Airflow

- Temperature

Highly sensitive to substrate variability – changes in…

- Board density

- Moisture content

- Coatings/recycled content

…can significantly affect bond performance from one batch to the next.

Environmental conditions matter – high humidity, low temperatures, or poor airflow can slow drying and reduce consistency, especially in seasonal or non-climate-controlled environments.

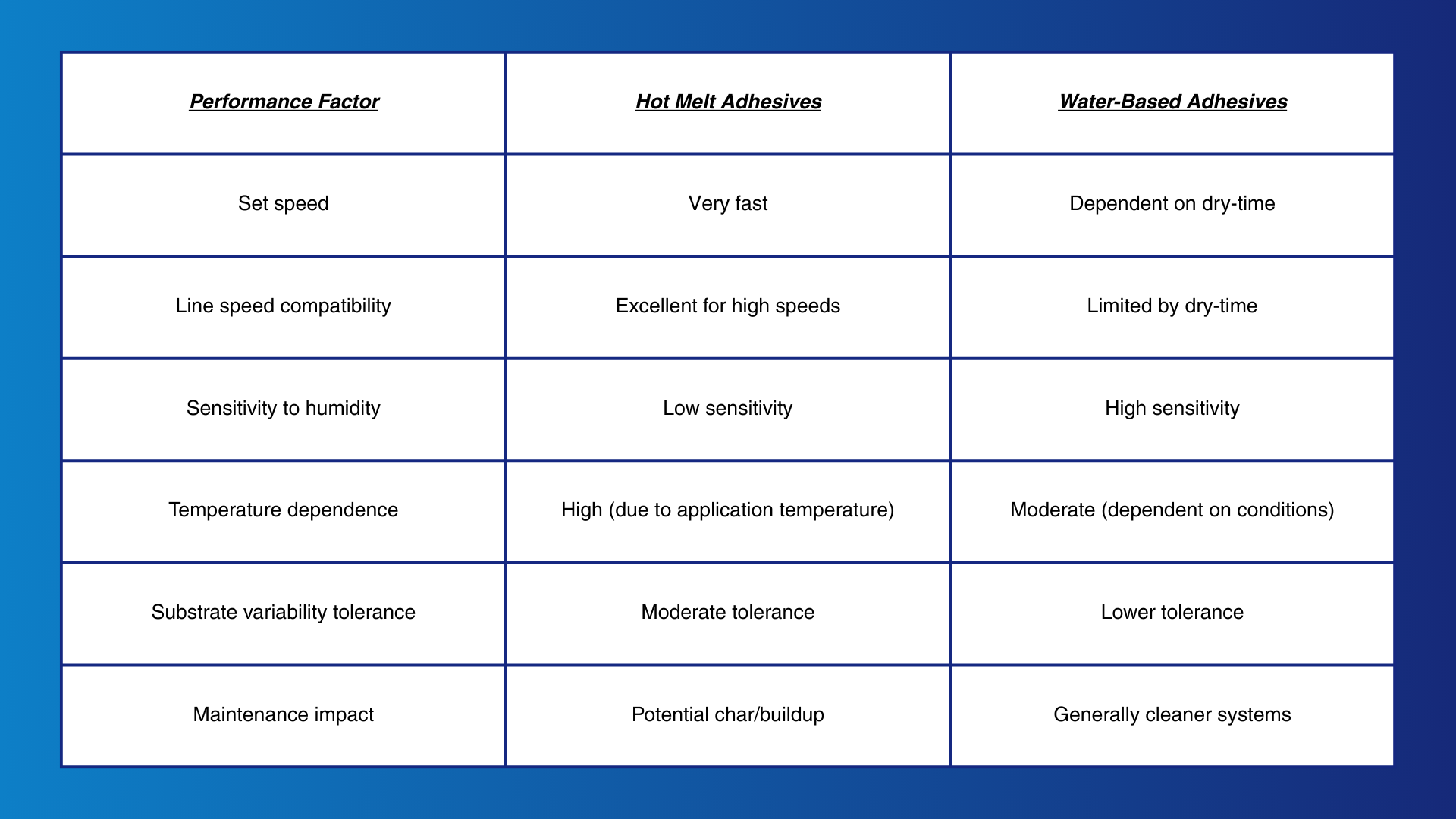

Side-by-Side Performance Comparison

Choosing by Application, Not Adhesive Type

Instead of asking “Should we use hot melt adhesives or water-based adhesives?”, ask a more productive question…

What does our process demand from the adhesive?

Hot melt adhesives tend to perform best when:

- Speed and immediate handling matter

- Environmental conditions are variable

- Downtime from slow bonding is unacceptable

Water-based adhesives tend to perform best when:

- Wide area coverage is required

- Substrates are consistent and porous

- Line speeds allow for proper dry times

In many facilities, both technologies coexist, each selected for specific stations or applications based on performance, not preference.

Hot Melt Adhesives vs. Water-Based Adhesives: Making A Decision

Adhesive performance is shaped by equipment setup, substrate variability, environmental conditions, and operator practices. No adhesive technology succeeds in isolation.

If your team is evaluating hot melt adhesives vs. water-based adhesives and is struggling with inconsistent bond strength, downtime, or changing materials, the solution often starts with application-specific evaluations, not product trial and error.

AJ Adhesives works with buyers, maintenance teams, and operators to assess how adhesive choices perform in real production environments to help you make confident, informed choices while reducing downtime and inconsistencies.

Ready to find the solution for your line? Contact your AJ Adhesives representative today!

Ready to find the solution for your line? Contact your AJ Adhesives representative today!

To speak with someone immediately, call: (314) 652-4583

For more information or questions, email us at: info@ajadhesives.com

Follow us on LinkedIn & Facebook for more tips, resources, and updates!