News

AJ Adhesives, Inc. – Holding North American Manufacturing Together.

Industrial Adhesive Applications: What Really Drives Performance on the Production Floor

In manufacturing, industrial adhesive applications rarely get attention when everything is running smoothly. However when bonds start to fail, cases open, or downtime creeps in, adhesives suddenly become a top concern for operators, maintenance teams, and purchasing departments alike.

What many experienced professionals discover over time is that adhesive performance isn’t determined by chemistry alone. It’s shaped by how the adhesive interacts with equipment, substrates, line speed, prolonged heat exposure, and real-world operating conditions that directly impact production floor adhesive performance.

This application deep dive looks at industrial adhesive applications from the production floor outward, highlighting what truly influences performance — and what teams can do to improve reliability without unnecessary changes.

Why Industrial Adhesive Applications Fail on Production Lines

In most manufacturing environments, adhesive failures are rarely random. They are usually the result of small changes that compound over time.

Across hot melt adhesive applications in packaging and assembly operations, three factors account for many adhesive-related issues: prolonged heat exposure, compression time, and substrate variability.

- Pot Stability Matters

Most operators track adhesive temperature, but prolonged heat exposure and pot stability often matter more.

Adhesives exposed to heat for extended periods can change behavior even when running within recommended temperature ranges, directly impacting production floor adhesive performance over the course of a shift.

Common production floor symptoms include:

- Inconsistent bead shape

- Poor wet-out on corrugate or paperboard

- Increased stringing or tailing

- Gradual loss of bond consistency over a shift

The longer an adhesive remains molten — especially through multiple heat cycles — the more likely its flow and set characteristics will drift.

Production Tip: Two identical adhesives at the same temperature can behave very differently depending on dwell time in tanks, hoses, and guns.

- Compression Time vs. Adhesive Set Speed

In adhesive performance on high-speed lines, set speed is often the focus — but compression time is equally critical.

When compression and set speed are mismatched:

- Adhesives can skin over before going under compression

- Bonds may appear strong initially but fail downstream

- Case integrity suffers during palletization or transit

Even high-performing packaging line adhesives will struggle if compression time changes due to speed increases, worn belts, or equipment adjustments.

Production Tip: Adhesives must be evaluated at real line speeds and compression conditions — not just by technical data sheet values.

- Substrate Variability Is Increasing

Modern packaging materials are more variable than ever, especially with higher recycled content.

Changes in corrugate and paperboard can introduce:

- Dust and fines that interfere with adhesion

- Inconsistent absorption across flutes

- Surface energy variation between batches/lots

Often, the adhesive reacts first — before operators realize the substrate has changed.

Production Tip: When adhesive performance drifts slowly over time, substrate variability is frequently the root cause.

Hot Melt Adhesives Beyond “Stick and Set”

Hot melt adhesives remain a core solution across packaging and assembly because they support fast production speeds and clean application.

However, experienced operations evaluate hot melts based on flow behavior, thermal stability, and consistency over time — not just initial bond strength. This approach is essential when making informed adhesive selection for manufacturing environments with demanding throughput requirements.

What matters most in real applications:

- Stable viscosity under prolonged heat exposure

- Clean cutoff for consistent bead placement

- Reduced degradation that limits adhesive char and buildup

Hot Melt Adhesive examples:

- AJ 1910 – a premium light-colored hot melt packaging adhesive used for tray forming & case and carton sealing. Very heat-stable product with excellent clean machining properties.

- Application temperature: 340-360˚F

- Viscosity at 350˚F: 785 cPs

- TM 450 – low application temperature hot melt adhesive for food or beverage tray forming & case and carton sealing. Heat-stable product with low odor, light color, and fast set speed.

- Application temperature: 250-300˚F, recommended at 275˚F

- Viscosity at 275˚F: 1010 cPs

This product highlights an important concept: matching adhesive behavior to line conditions reduces operator intervention, improves throughput, and reduces waste – all key contributors to lowering cost of use adhesives in real-world production floors.

What Purchasing Teams Should Consider Beyond Price

For purchasing departments, adhesive selection is most effective when evaluated on cost of use adhesives, not cost per pound or unit alone.

Operational factors that influence real cost:

- Downtime related to adhesive instability

- Maintenance tied to build up or char

- Waste caused by inconsistent bonding

- Labor spent adjusting temperatures or settings

Aligning purchasing decisions with production feedback leads to better adhesive selection for manufacturing operations and fewer reactive changes. Even though the price looks good on paper, the lowest cost adhesive doesn’t always generate true savings on the production floor.

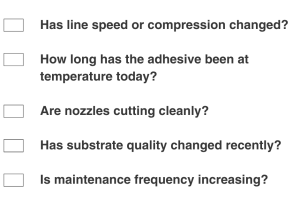

Operator Troubleshooting Checklist – Is it really your adhesive?

Before pointing fingers at your adhesive of choice, ask yourself:

If any answer is “yes,” the issue may be application-related rather than adhesive-related – a key component in effective industrial adhesive applications troubleshooting.

AJ Adhesives Hot Melt Troubleshooting Guide

Industrial Adhesive Applications Are Just One Part of Your Production Line

One of the most valuable realizations for experienced professionals is this: adhesives do not operate independently — they function as part of a system.

When adhesive formulation, temperature control, equipment setup, substrates, and operator practices align, bonding becomes predictable and reliable — even in demanding adhesive performance on high-speed lines. Adhesives don’t just decide when to work and when not to work, if there’s an issue, a variable on the line has changed.

That understanding is what separates reactive troubleshooting from proactive line optimization.

Ready to discuss what will be best for your line? Contact your AJ Adhesives representative today!

Ready to discuss what will be best for your line? Contact your AJ Adhesives representative today!

To speak with someone immediately, call: (314) 652-4583

For more information or questions, email us at: info@ajadhesives.com

Follow us on LinkedIn & Facebook for more tips, resources, and updates!